Small compost turner is the equipment developed by our company. Especially for small farmers and small factories to produce charcoal-based fertilizer. They are not only particular designed to provide assistance in the fermentation and turning of charcoal-based fertilizers. But also can recycle agricultural waste. More importantly, this machine sell-best in our company for many years, it also praised by other suppliers.

What are all the small composters in biochar-based fertilizer

3 types of compost machine

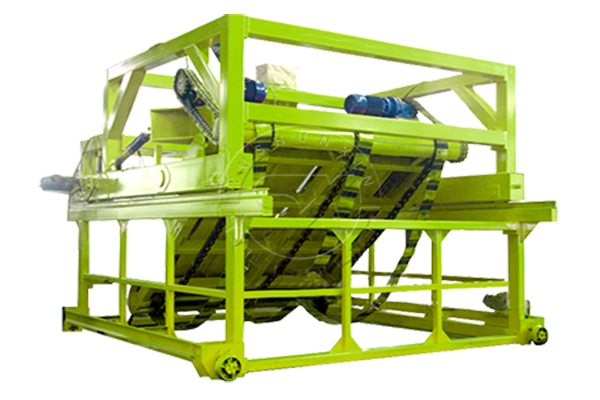

Groove compost turner

If you want a more convenient and productive way of composting. Then you can choose a compost turner that can work in the fermentation tank. Because the fermenter is mounted with pulleys, the machine can slide on top of the fermenter. Besides, no need for human control all the time.

Chain plate turner is suitable for crushing charcoal-based fertilizer materials. It has well adaptive for carbon-based fertilizer. More importantly, the machine has the advantages of smooth operation, high efficiency, and can turn the charcoal-based fertilizer in depth. Undoubtedly, the machine can not only shorten the fermentation of charcoal-based fertilizer materials but improve the production efficiency of fertilizer.

Windrow type compost turner

If you want a program with a little bit better price, then you can choose windrow type compost turner machine. It has two kinds of equipment of our company. One is a crawler type compost turner and the other is a moving type compost turner. And they are one of the most money-saving modes of composting available. Because it saves money on building fermenters.

Although the price is favorable, the production is still relatively large. The capacity of this equipment can reach 500-700m3/h. Besides, the machine adopts four-wheel walking design, which can go forward, backward and turn. Most importantly, it is operated and driven just by one person. And it can work in the greenhouse or outdoor open field.

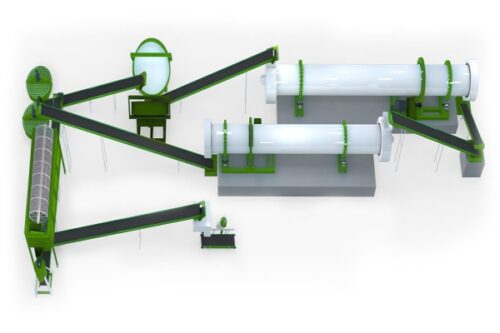

Organic fertilizer fermenter

If you want a stable and fast fermentation method, then you can choose our organic fertilizer fermenter tank. It is also a type of small composting machine. Our company according to the shape is divided into two types of horizontal fermenters and vertical fermenters.

Our fermenter is fully automatic closed fermentation, so it will not be disturbed by the external environment. So, it is more stable. And the machine monitors temperature and moisture in real time, it will be faster than other compost turner. And the fermenter only covers an area of 10-30 square meters, small footprint. For you, it must be the ideal equipment for the manufacture of charcoal-based fertilizer.

How to make charcoal-based fertilizer using small compost machine

The process of pre-composting treatment of charcoal-based fertilizers is divided into the following steps. And it also can use by small compost turner:

When is the best time to use small compost to making charcoal-based fertilizer?

To compost charcoal-based fertilizer fast, you should make in spring, summer and autumn. Because these seasons have higher temperatures. It not onle easily promote the decomposition of organic matter. But also help fermentation time faster. Furthermore, it saves labor and cost. However, the specific time should be determined according to the local climate and the availability of charcoal-based fertilizer raw materials.

But what if it’s winter? For winter, we recommend two options. One is to use our horizontal fermenter or vertical fermenter. The second one is you can use groove compost turner, we can heat the temperature by piping under the fermenter for you.

How much does small compost turner cost

The price of groove type compost turner machine is about $6,500 – $23,000.

Windrow compost turner cost around $6,000 – $13,000. Also, the wheeled tumbler has a better price.

Fermenter pot cost about $150,000.

What’ more, depending on the type and the output size is different and the price will also change.

Why you need to compost?

Functions of small composters

Small composter is a kind of charcoal-based fertilizer composting equipment for small farms or small production lines. It can help to convert agricultural waste, corn stalks, peanut shells, etc. into charcoal-based fertilizer. So it is environmentally friendly and energy-saving.

Functions of compost

Charcoal-based fertilizer compost is the use of a variety of organic wastes as the main raw material, by the heap system of decomposition into organic fertilizers.

What’s more, composting is a important process of producing charcoal-based fertilizer. Because one reason is compost produces high temperatures of 60 degrees or more to kill disease and insect eggs and weed seeds. The other is if raw materials that have not been composted are given directly to the plants, this can result in temperatures that are too high to burn the plants.