what are the raw materials for 30 TPH large biochar powder fertilizer production line?

First, when you need to prepare biochar powder fertilizer, then you need to prepare the ingredients. There are two main types of raw materials for charcoal-based fertilizer, one is carbon and the other is organic fertilizer.

How to design a 30 TPH large biochar powder fertilizer production line?

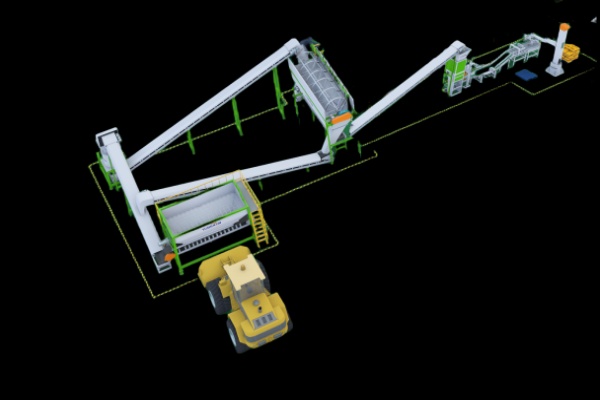

If you consider the location of your biochar fertilizer plant, then you need to consider how to plan your fertilizer production area, our company for you to plan a free 30-ton per hour large charcoal-based powder fertilizer production line. What’s more, In the planning of our large biochar fertilizer powder fertilizer production line. the length is one hundred meters and the width is 96 meters. And it consists of a total of 4 parts. Here’s a more detailed description of the region:

- Aging area is a designated space where the compost or organic material is allowed to undergo further biological decomposition and stabilization. This step is crucial in the production process. Besides, The width of our aging area is 24 meters wide and 100 meters long.

- It used for fermentation and composting of raw organic materials and biochar. Besides, it can adopt the form of fermentation groove, fermentation tank or composting field. If you want a continuous and stable fermentation, we recommend a fermentation tank. Furthermore,We have two fermentation areas, the size of one fermentation area is 100 meters long and 24 meters wide. So two fermentation areas are 48 meters wide and 100 meters long.

he finished product stacking area is a crucial part of the biochar powder fertilizer production plant. This area is designated for storing the processed biochar powder fertilizers before they are packaged and distributed.

So It should keep well ventilated and preventing moisture. And this area can help you maintain the quality and effectiveness of biochar powder fertilizers. And, our production area and product storage area are shared. It is 100 meters long by 24 meters wide. This saves space and saves you money.

How to choose 30 TPH large biochar fertilizer plant locations?

After you’ve prepared your ingredients, you’ll need to plan your charcoal-based fertilizer site. Only if you build a fertilizer plant first can you place your large biochar powder fertilizer production line:

How much cost is required to set up 30 TPH large biochar fertilizer plant?

Our company can manufacture up to 30 tons of large biochar powder fertilizer production line. This is a significant scale of production that can meet the requirements of large scale fertilizer production. And we’re in the $140,000 to $160,000 range. Prices will vary depending on your machine.

if you need a biochar drum dryer machine to dry your line before pelletizing, the price will increase. This machine is not included in the base cost of the fertilizer production line, but it’s a crucial addition if you want to ensure the highest quality of your biochar powder fertilizer. If you have a number of machines and are just adding to your existing machines, the price will decrease.

What fertilizer equipment is needed for a 30 TPH large biochar powder fertilizer production line

What equipment do you need for your carbon-based fertilizer plant? There is no doubt that you requires a array of equipment. So that can designed to process raw materials into finished products. And below is essential equipment.

Two 22 m biochar wheel compost turners.

C harcoal-based fertilizer wheel compost turners have several uses, 1 to promote the decomposition of organic matter, 2 to regulate the humidity in the compost, 3 to control the temperature of the compost, 4 to prevent the charcoal-based fertilizer material caking.

A SXFLF-1200 biochar vertical type crusher

TThe main function of biochar fertilizer crusher is to pulverize organic and carbon based raw materials into carbon based powder suitable for subsequent processing.

A SXGS-2080 biochar screening machine

Carbon based fertilizer sieving machine can classify the crushed fertilizer powder by particle size. It separates the powder that meets the requirements from larger particles or lumps. This can ensure that the finished fertilizer powder particle size uniformity and improve product quality.

A biochar powder packing machine

The role of bagging machine in charcoal based fertilizer powder line is to package the finished production of fertilizer powder. To make it easy to store, transport and sell.

These are the basic facilities for the production of our basic charcoal based fertilizer powder line, if you want to reduce or buy other facilities, you can communicate with our sales staff.