New type organic fertilizer granulator, which is one of the huge granulator machines in our factory. This machine can not only granulate a variety of organic materials, also especially for charcoal-based fertilizer granulation. And fertilizer granulator machine has many benefits than other granulator machines. For example, long use and long life. And it can fit to manufacture whose have plenty of fertilizer.

Top 4 advantages of New Type Organic Fertilizer Granulator in carbon-based fertilizer

Organic fertilizer granulator plays an important role in the production process of carbon-based fertilizer, the granulator machine in our company has many advantages, and then I will tell you these from 4 aspects.

Special technology and method

Fertilizer granulator machine suitable for Granulation – Wikipedia. This way can make easy compression molding, good appearance, and easy to transport in making biochar-based fertilizer. It use of high speed rotary mechanical agitation force and resulting aerodynamic force. This makes fine powder materials continuously achieve the process of mixing, granulating, balling and densification in the machine. So as to achieve the purpose of granulation. This granulation method has high granulating rate, the granule is more beautiful, and save energy.

Long life and less maintain

First, the fertilizer granulator machine is made of stainless steel, because our factory wants it use longer. So, it is sturdy and durable. What’s more, the lower part of the machine is made of multiple brackets, which makes the machine more solid. And the internal gears are made of manganese steel, which is corrosion and wear resistant. Furthermore, our organic fertilizer granulator will be less frequent maintenance.

Larger capacity and higher efficiency

In generally, the new type of organic fertilizer granulator has large capacity when compare with another granulator machine. It bigger than it’s volume. In our factory, this machine is one of the best-selling because is larger capacity. We have Five model, one of the smallest outputs is 1-1.5t/h, the power is 37kw/h. The production capacity of medium models is 2-4t/h, the power is 75t/h. And the largest one is 6-8t/h, the power is 110kw/h. So, you can pick it up that fit your factory.

High granulation rate

This new organic fertilizer granulator machine not only has high efficiency but also has high granulation rate. The rate of the fertilizer granulator manufacturers is very high in the fertilizer line. And the pelletizing rate is more than 95%. It as high as disc granulator. What’s more, the pelletizing rate of the disc pelletizer is almost high. So, if you want to buy a machine have high granulation, organic fertilizer granulator machine must be the best choice.

How to maintain the machine in char-based fertilizer?

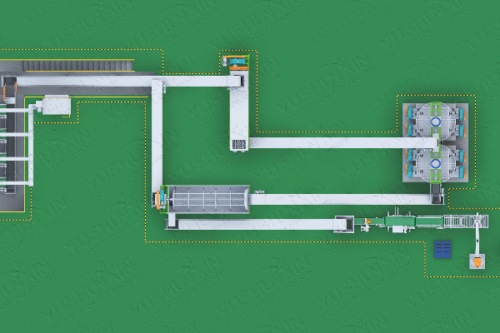

The structure of New Type Organic Fertilizer Granulator

First is Frame part, All the equipment of the machine is installed and fixed on the frame, the frame is made of steel plate, strong and durable, in line with national technology requirements, to achieve the standard of machine can be used. Second is churning part, this is the most important part of the machine, powder from the inlet through the spiral blade drive into the mixing frame, through the mixing teeth of the mixing, to achieve the purpose of particles. Third is Transmission coupling part, to make the drive reducer and the head of the working part work.