With the government’s support and also because of the advantages of the carbon-based fertilizer. So, biochar fertilizer has become more and more popular. If you want to establish a carbon-based fertilizer factory, then you will be considering the relevant equipment and the materials. Obviously, the later will get easier than former. So you can choose our company we can help you find biochar fertilizer machine that suitable for you.

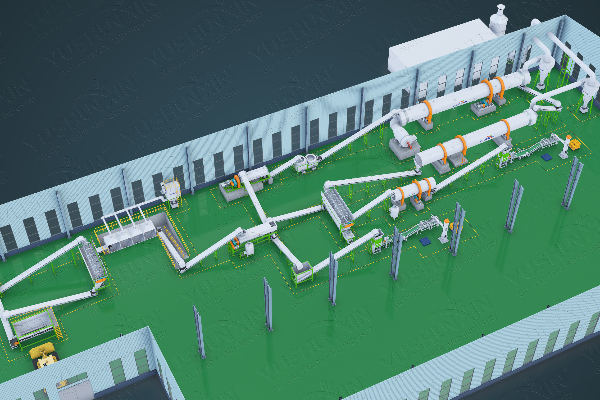

Biochar fertilizer production line in ShunXin company

In order to better make biochar-based fertilizer, ShunXin company can offer all kinds of biochar-based fertilizer machine for you. For example, we have Double Roller Extrusion Granulation Production Line. Powdery Biochar Fertilizer Production Line. Disc Granulation Production Line. The above production lines will surely meet your various needs. What’ more, you can utilize our machines and equipment to create other lines, such as organic waste recycling lines.

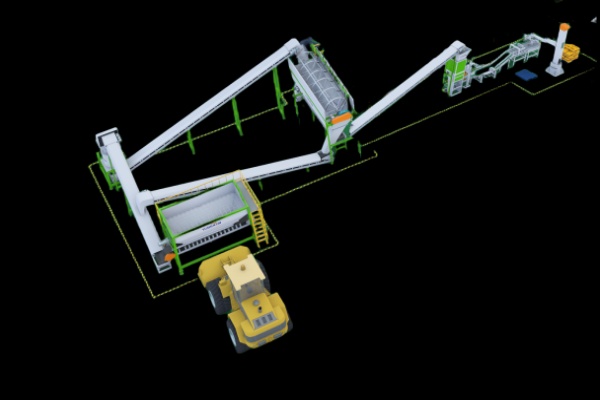

Double Roller Extrusion Granulation Production Line

At present, the extrusion pelletizing method is a simple process, easy to operate. Now is favored by many companies. Not only because of the small footprint of the extrusion pelletizing equipment, but also its high efficiency. So, then I will tell you the roller extrusion pelletizing principle.

After you mix the biochar-based fertilizer materials and charcoal with reasonable combination and measurement. The materials are transported to the mixer through the elevator to mix. This is because after mixing, the two materials need to be stirred evenly to facilitate the material’s subsequent pelletizing procedure. The material will then be transported to the drum extruder for extrusion granulation. Pelletizing facilitates the transportation and storage of the material. Then after screening and anti-caking treatment by the screening machine, it can be packaged and stored by the baling machine.

Double roller extrusion pelletizing process adopts roller pelletizing equipment. It is simple machine in biochar fertilizer machine. Through the strong pressure generated by the roller press, the powdered material is instantly extruded into shape. So, it is very simple to make granule. It uses various shapes of molds in it. If you want to change the shape and size, you can just change the mold. And this machine is easy to maintain and has low running cost.

Extrusion pelletizing process and equipment

The extrusion pelletizing process mainly consists of double roller type and flat die type. Moreover, extrusion pelletizing is a dry pelletizing process. The material is extruded by the mold, and no water is added during the extrusion process. And no need for drying after pelletizing.

carbon based fertilizer equipment

Fermentation compost equipment

In all kinds of biochar fertilizer machine, the most important machine is compost turner. The main function of the turner is to turn, ferment and crush the garden waste. Through the treatment of turner, garden waste can be fully fermented, rotted, kill harmful microorganisms and insect eggs, and transformed into high-quality charcoal-based fertilizer.

Crushing Equipment

When producing carbon-based fertilizer, you need to use a crusher, so that both the lumpy carbon-based fertilizer raw materials or bonded together raw materials, you can choose the appropriate crushing equipment to crush and pulverize them for subsequent packaging or deep processing treatment.

Fertilizer Mixing Equipment

In biochar fertilizer equipment. Mixer has a very important role. suitable for continuous mixing of charcoal-based fertilizer powder, our company’s mixing equipment, with its very stable performance and technology has been widely recognized and praised.

Fertilizer Granulating Equipment

In charcoal based fertilizer production line. For better transportation and storage of fertilizers, you need to use granulation equipment to make them into granules. After granulation, the charcoal-based fertilizer can be more conveniently applied to agricultural production. So, granulator machine is an integral part of the biochar fertilizer machine.

Drying and Cooling Machine

Carbon based fertilizer raw material moisture content are relatively high, although after fermentation, crushing and mixing, conveying these processes, the material moisture content has been reduced, but the reduction is relatively small. Therefore, granular organic fertilizer production line process is inseparable from the dryer, cooler.

Why you should choose Shunxin company

you can be assured of our company’s products, first we can give you advice to choose you favority churing granulator, second we have perfect after-sales service.

Experienced: Our factory has a thirty-year history, an experienced team, and advanced science and technology imported from abroad. So, if you choose our biochar fertilizer machine, you can don’t worry any problems.

Cheap budget: We have our own factory, you tell our customer service your budget, we can make the charcoal-based fertilizer production line for you according to our own experience, within your budget.

Special Customization: If you want to customize some parts on the equipment, or change your favorite color, our factory can meet your requirements.