What is compost turner machine?

This machine is the most popular compost turner machine in our company. And it is one of the equipment for many manufacturers and producers. Besides, it has two types. One is crawl compost machine. The other is moving compost machine. If you want to produce carbon-based fertilizer, then you need a self-moving type of compost turner. Because it can help you turn the charcoal-based fertilizer so that your materials can fester other mixing. This equipment is designed specially, so it is very simple to drive it. Besides, it’s just drove by one person. Besides, it can move forward, backward, and turn around.

The advantages of self-moving compost turner in carbon-based line

Modern technology

The machine is an ideal equipment, which uses modern technology to turn straw or organic matter into carbon-based fertilizer. It is very convenience for producer and manufacturer. Because it is not only low cost but low energy consumption. What’s more, it has large output in the fertilizer production line. Also, this product is suitable for bar and stack fermentation on the ground, and it is a pattern that production line of carbon-based fertilizer. Besides, the machine takes four-wheel walking design, and is controlled by one person. Not only can walking on the open space, but also in the workshop.

Increase efficiency

Fermentation piles in the ground require biochar-based fertilizer to be piled into long stripes. This needs a self-moving compost turner to mix and crush regularly and timely. The decomposition of organic matter under aerobic conditions will be conducive to crushing charcoal-based fertilizer materials. So it greatly saves time and labor, significantly improves the production efficiency and product quality of carbon-based fertilizer, and highly reduces the cost. Furthermore, It can reach one day of heating, 3-5 hours of deodorization, and seven days of fertilizer. lt is not only much faster than the fermentation method using other mechanical means, but also much more efficient.

Protect environment

A compost turner machine is equipment that can mix, stir, and organic matter. The biochar-based fertilizer materials include animal manure, coal, slag, and other organic matter. And then through the principle of aerobic fermentation. The equipment provides a better environment for carbon-based fertilizer. Not only that, after fermentation of the material by the turner, it can improve the environment. What’s more, it improves the soil quality of biochar-based fertilizer. Self-propelled pile tiller plays an important role in protecting the land environment and reducing soil pollution.

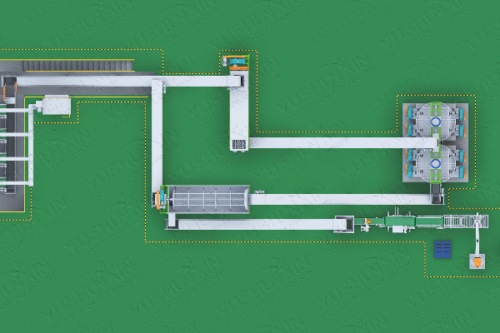

How to make granules by using carbon fertilizer granulator

The production of charcoal-based fertilizer raw materials are relatively wide. The more common is wheat straw, rice hulls, garden waste and so on.

Benefits of using a turner for charcoal-based fertilizer

Provide oxygen

Composting can provide sufficient oxygen inside the charcoal-based fertilizer, so that the material will not be in anaerobic state. The current composting process advocates high-temperature Aerobic fermentation process, if the internal anaerobic compost will make the material produce an unpleasant ammonia smell, polluting the environment.

Adjusting the moisture

The appropriate moisture content for raw material fermentation is about 55%. But the moisture standard for finished charcoal-based fertilizer is below 20%. And turning the carbon-based fertilizer materials will form mandatory water vapor emanation. It can be with the process of fertilizer production in time to reduce the water.

Making temperature lower

When temperature is higher than 70 ℃, if not compost, most of the microorganisms in the compost will be killed. The most critical is that such a high temperature will accelerate the decomposition of the material. Besides, the loss of the material will be greatly increased, so the temperature is higher than 70 ℃ is not good for composting.

Why do you choose our company?

Our company has 30 years of experience, and has a top level of technology and an experienced team. Moreover, our company is fully committed to the research, development and promotion of charcoal-based fertilizer equipment. And our company is equipped with a large number of advanced processing equipment. The company was founded in 2005, after years of reform and development, and has achieved numerous honors. The company’s equipment specifications are complete, the quality is excellent, and all indicators meet or exceed the national standard. In the end, If you want to buy our products, you can contact us, our staff will provide you with more detailed parameters and prices.