Carbon granule machine in Africa

A customer who comes from Africa, and told us he wanted to buy a carbon granule equipment, and he asked if we have the machine have high efficiency and high granulating rate. Besides, he said he didn’t have a composting initial, so the main ingredient had a lot of moisture content. He want to know if we have the machine can fulfil these conditions. What’s more. Guests say they must also cater for a granulator with a capacity of 8 tonnes per hour.

What fertilizer production line does customer fit?

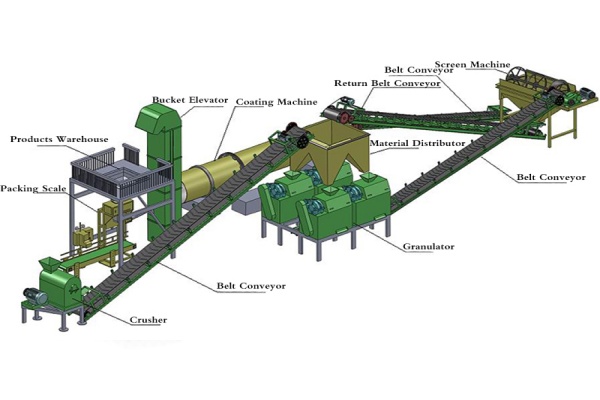

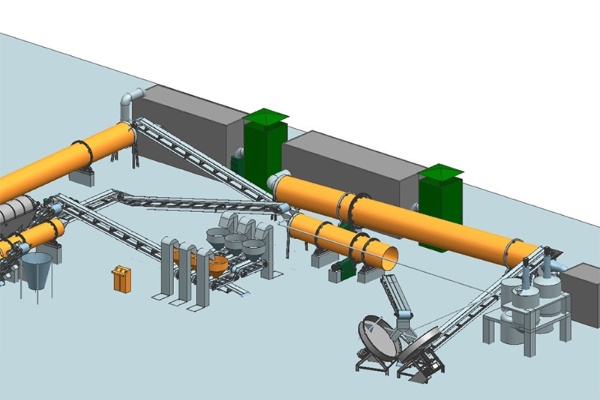

We suggest that guests can use the double roller extrusion granulation production line and disc granulation production line.

Double roller extrusion production line

This series of roller granulator adopts the principle of physical extrusion to process the powder material into the required shape granule. It has the advantages of compact structure, low energy consumption. And can form a small production line with the corresponding equipment.

disc granulator fertilizer production line

Disc granulator mainly used for the production of granular organic fertilizer. It is usually used in conjunction with pulverizer, dryer, sifter, packing machine and so on. What’ more, it has the advantages of easy transportation and beautiful granules.

Any other questions from the guests?

When you want to produce the biochar-based fertilizer in your factory, you should know why you need to use organic fertilizer polishing machine.

The customer also asked us he wanted a machine with an output of more than 8 tones per hour, which one would be more suitable for him? Both of these machines are capable of producing up to 8 tones per hour. Whether it’s a disc pelletizer or a drum rotary machine, their output is relatively large.

In the end, the customer finally chooses the disc granulator, because it has the high efficiency while the price is low. The customer said he would like to buy other things from us next time for the pelletizing line. We also have other equipment in our pelletizing line, such as fermentation compost equipment, crushing equipment, fertilizer mixing equipment, fertilizer granulating equipment and cooling machine.