What are the Advantages of 5 h/t Biochar Fertilizer Double Roller Production Line?

There are a total of three advantages about the charcoal-based fertilizer roller granulation production line:

Our carbon based fertilizer double roller granulator can produce up to 2 tons per hour of biochar fertilizer. The biochar fertilizer double roller granulation line allows for continuous and large scale production of carbon based fertilizer and this ensures a stable output. So it’s perfect for charcoal-based fertilizer fertilizer applications that require high capacity operations.

The biochar fertilizer double roller granulation line can ensures uniform and consistent pellet size and shape. It is critical for subsequent consistent application of carbon based fertilizers. Besides, it produces pellets that are typically denser and more durable, which improves storage time and not break during transportation.

The biochar fertilizer double roller granulation line can ensures uniform and consistent pellet size and shape. It is critical for subsequent consistent application of carbon based fertilizers. Besides, it produces pellets that are typically denser and more durable, which improves storage time and not break during transportation.

arbon based fertilizer roller granulator is designed to be more energy efficient and can significantly reduce operating costs in the long run.

And, compared to other types of granulators, our carbon based fertilizer roller granulators are usually very robust and durable. It requires less maintenance, which reduces downtime and maintenance costs.What are the types of 5 t/h biochar fertilizer double roller granulation line?

If you need 5 t/h biochar fertilizer double roller granulation line, then we can recommend you two options.

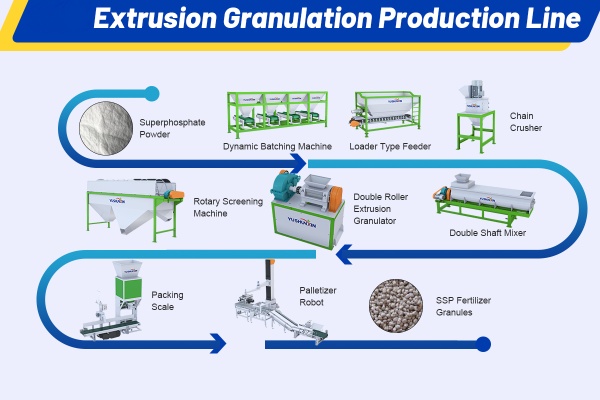

What is the process of 5 t/h biochar fertilizer double roller granulation line?

If you want to buy our biochar fertilizer double roller granulation line. Then we will introduce you specifically what production processes it includes:

What is the dry granulation method used in 5 t/h biochar fertilizer double roller granulation line?

ry granulation is a process used to manufacture charcoal-based fertilizers. This method converts a powder or powder mixture into granular form. But, it is different from wet granulation which uses a liquid binder to bind the granular aggregates. Dry granulation is achieved by compaction. So it must be the best method and choice for your extrusion pelletizing.

he process begins with the pre-compaction of the biochar powder, followed by passing the compacted material through a mill or granulator. The pellets are then further processed through sieving and packaging steps. Only then can the final charcoal-based fertilizer pellets be produced. Moreover, the charcoal-based fertilizer pellets produced in this way are economical and high productivity.