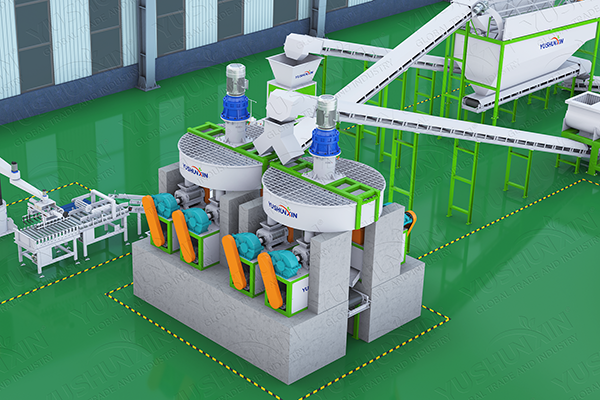

What is the double roller extrusion machine?

Double roller extrusion granulator is the best machine. At the same time, it is the most selling equipment in our factory. Double roller presses granulators play a pivotal role in transforming raw carbon-based materials into high-quality granules. Furthermore, it has many advantages compared with other granulator. For example, it compared with new type drum granulator, it needn’t to dry the pelletes. What’s more, if you have trouble in choosing a double roller granulator machine, we will help you in a couple of ways.

How does the double roller extrusion granulator operate?

How double roller extrusion granulator works?

It is driven by the electric motor with a belt and pulley, And it is transmitted to the main shaft through the speed reducer to work. The material is added from the feed hopper, extruded and molded by the wheel, molded to make balls. Then transferred to the crushing and screening room through a pair of chains to screen and separate the finished particles. After that, then return the old biochar-based fertilizer material to mix with the new material and pelletize again.

What’s the principle?

With the continuous materials are continuously entering before mass production can be realized. In addition, the impact of squeezing is to push the air between the particles. What’s more, it makes the distance between particles getting more closer to produce adsorption and the force of attraction, and so on. Extruded pelletized particles are mainly formed by the strength of the particles by the forces between molecules.

| Model | Power(kw) | Granule Diameter(mm) | Roller Sheet Size(mm) | Dimensions(mm) |

|---|---|---|---|---|

| SXDG-1T | 15 | 3-10 | 150*220 | 1450*800*1450 |

| SXDG-1.5T | 18.5 | 3-10 | 150*300 | 1450*850*1500 |

| SXDG-2T | 22 | 3-10150*220 | 185*300 | 1630*850*1650 |